Guide ropes are fitted on the bottom side of a conveyor belt in order to aid proper tracking of the belt or deal with any shear force. Spill edges are fitted on the top side (carrying side) of conveyor belts in order to prevent product from falling off the belt. Guide ropes and spill edges can be obtained in a variety of designs (type of plastic, colour, shape, notched or smooth). Bandtransport Europe can mount the guide ropes and spill edges on your conveyor belt, or you can purchase them on rolls.

Apart from our standard range of PVC, PU and PE guide ropes, which generally have a hardness between 60° Shore A (PVC) and approx. 90° Shore A (PE, PU and TPU), Bandtransport Europe also supplies a number of special PVC guide ropes with hardnesses between 35° en 55° Shore A. These materials remain flexible for longer under cold circumstances and can be used on smaller drum diameters. For demanding applications Bandtransport Europe offers special notched guide ropes made of the very wear-resistant Hytrel® material.

Notched guide ropes can be machined according to your exact specifications on our special notching machine. All guide ropes and spill edges can be obtained loose, per roll. Due to our expert knowledge and skills regarding conveyor belt fabrication, we can also fit guide ropes or spill edges to your conveyor belts according to your specifications.

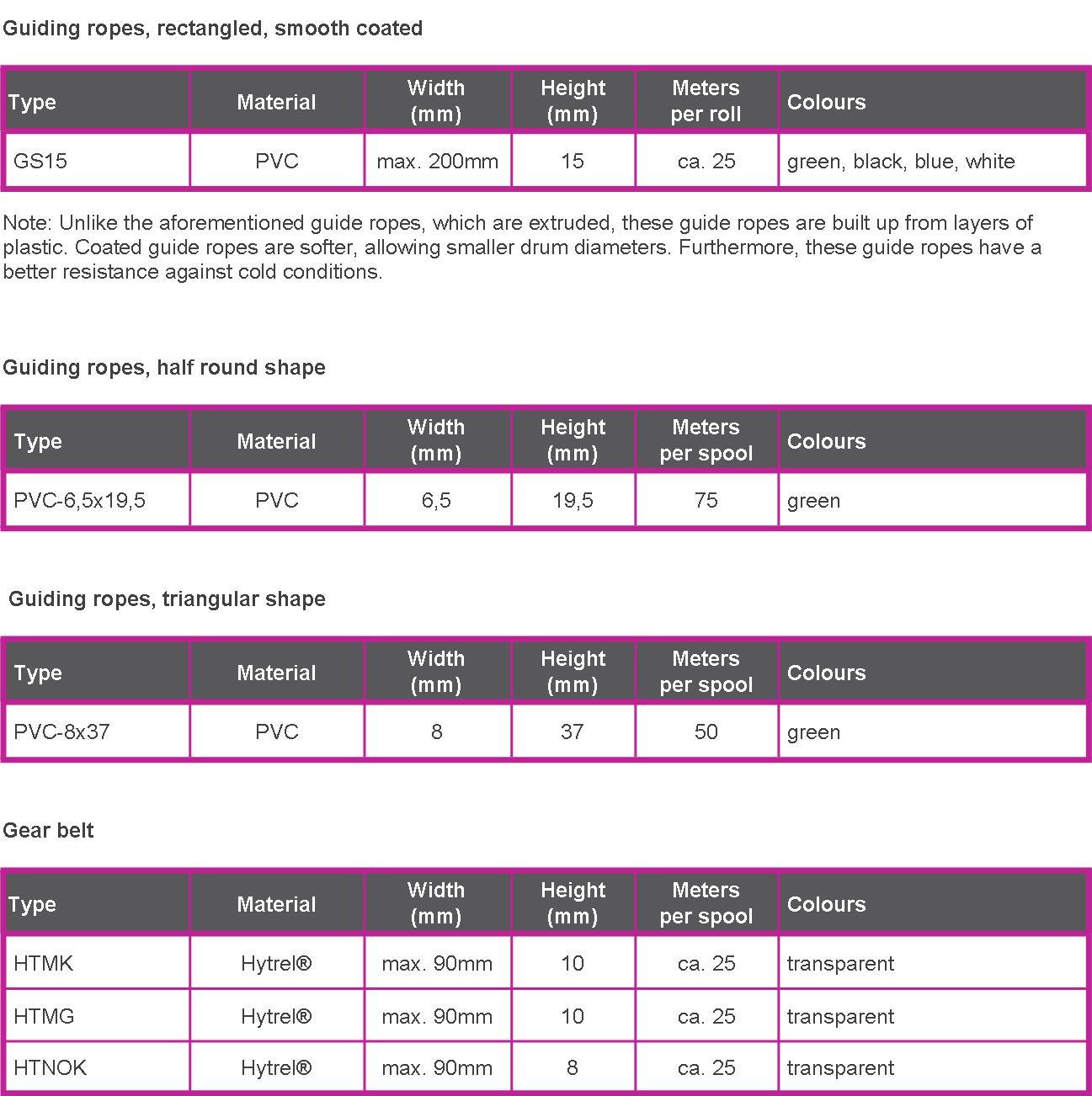

Below, you will find Bandtransport Europe's range of guide ropes and spill edges. Can you not find the design you need? Please feel free to contact us. It will be a pleasure to help you find the right product.

Please note: these are provisional data. For definitive data, please contact us.