New PU belt is in line with the latest developments in food safety and hygienic design, offering a.o. excellent cleanability. Can be supplied with several profiles, such as the 'sharp nipple' profile for meat and fish.

Where food is processed, hygiene is paramount. Food safety has priority: bacteria must not be given a chance. A conveyor belt that comes into direct contact with meat, fish or poultry must be cleanable quickly and thoroughly.

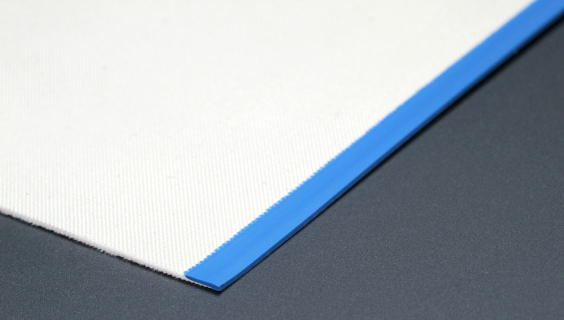

Bandtransport Europe is an expert in the manufacture of PU conveyor belts for hygienic processing of fish, meat and poultry. Belts with a polyurethane (PU) coating are easy to clean. The construction of the belt ensures that the coating of these PU conveyor belts cannot absorb moisture and dirt. Additional fabrication in our workshop makes it possible to completely seal the sides of the belt, to prevent moisture and bacteria from penetrating the inner fabric.

Bandtransport Europe is constantly working on putting together the best possible product range. Our products must be in line with the latest developments in the industry. New developments in food safety and the associated norms, standards and regulations are constantly changing the needs of belt users. At the same time, we look at the ease and speed of belt processing and their ease of use, e.g. during the factory cleaning process. In order to offer the right mix of conveyor belts, Bandtransport Europe recently added a new PU belt to its range: type UG27-85.

The new conveyor belt type UG27-85 has a top cover of 1 mm thick SPU with a hardness of 86° Shore A. Its easy-to-clean coating meets the requirements of FDA, USDA and EU, making it very suitable for food processing. The special fabric is antistatic, laterally stable and low-stretch, which improves the performance of the belt. Impregnation of the bottom side prevents dirt and moisture from penetrating the fabric. Further technical details for UG27-85 can be found in the datasheet.

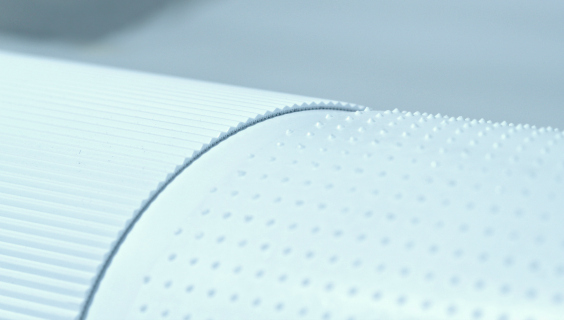

This new SPU belt type can be provided with the so-called 'sharp nipple' profile. We call this belt type UG27-85 (sharp nipple). This pointed profile - new in our range - ensures that poultry, meat and fish remain well positioned on the belt. The special cone shape of this profile enables easy and thorough cleaning, thus ensuring optimal hygiene.

At Bandtransport Europe you have the possibility to have your conveyor belt material embossed with a profile of your choice. Besides the sharp nipple profile, belt type UG27-85 can be supplied with, for example, the popular and often-used triangle and cone profiles. Feel free to contact us about your profiling preferences. A lot is possible.

Fabseal® seals off the sides of the conveyor belt, so dirt and moisture cannot enter the fabric. Not only does this ensure a very high degree of hygiene, it also extends the life of your belt: moisture can no longer penetrate the belt and irreparable damage due to delamination of the cover layer is prevented.

Belt type UG27-85 is also available in white under the name UG27-25. This belt is constructed of a two-layer, antistatic, low-stretch and laterally stable fabric with a 1 mm SPU top cover and an impregnated bottom side. It can be supplied with a smooth or a profiled cover. This belt also meets all FDA, USDA and EU requirements for food processing belts. Via the information page you can find out more about this belt type. If you have a MyBTE login code you can also find price information.

Bandtransport Europe is a specialist in conveyor belt fabrication. We concentrate entirely on the techniques, the craftsmanship and the little tricks that make the difference for a fully fabricated conveyor belt. By applying new techniques and solutions time and again, we make the difference in the finishing of your conveyor belts.

Belts with cleats, guide ropes, spill edges, corrugated sidewalls and sealed edges are expertly manufactured by our team. Open pieces, prepared joints or endless belts: we can offer you all you need. On our digital cutting machine we can cut complex designs and large quantities, including perforations, according to your exact specifications. Since we have the possibility to apply extra coatings or profiles in-house, we are flexible in our solutions.

'Ordinary' conveyor belts are our daily business, but we also love finding special solutions for special problems. Solutions we are proud of. Do you need a 'normal' conveyor belt, or are you looking for a special solution? Feel free to contact us.

Call us (telephone +31 (0)251 319 119) or send us an e-mail.